01

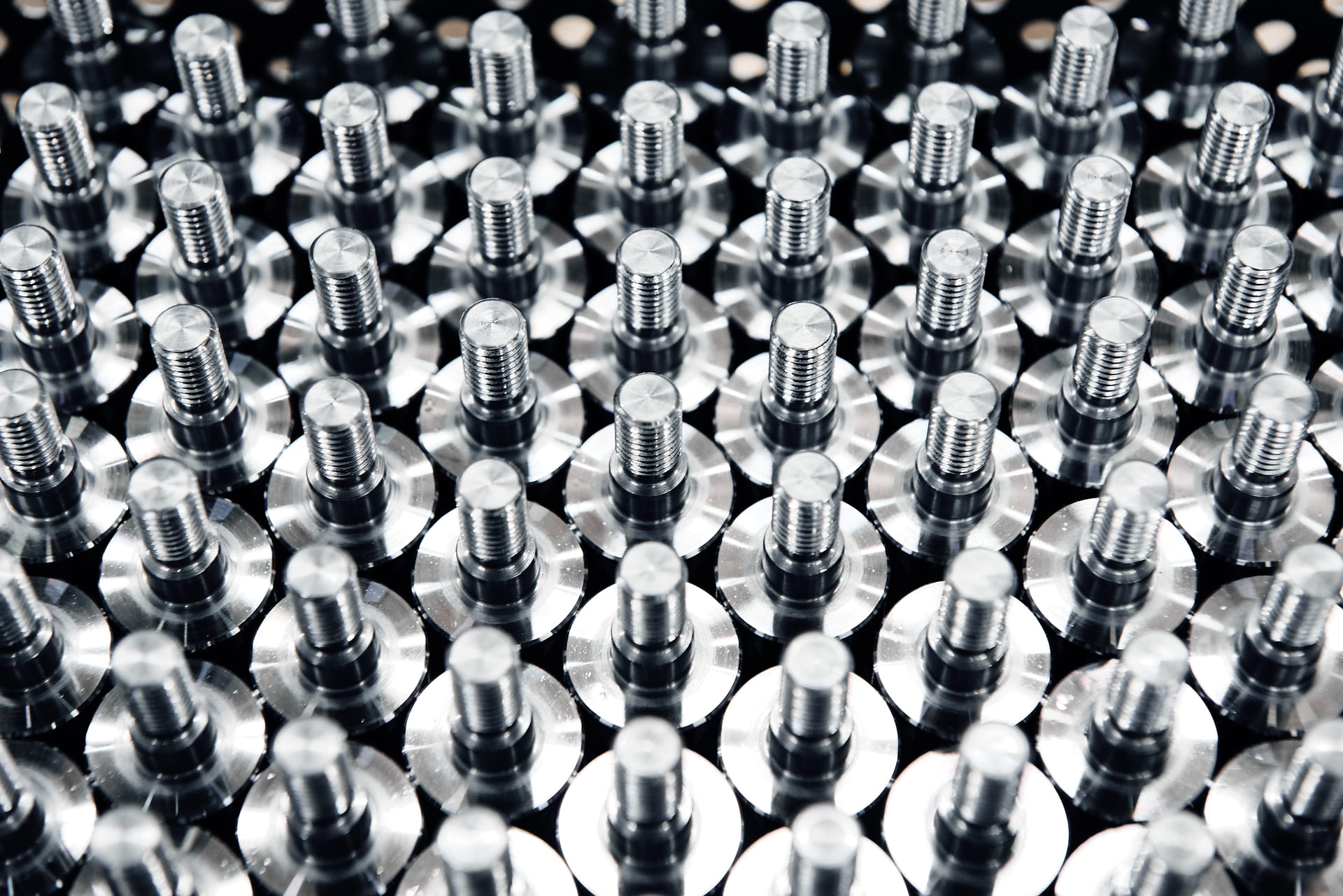

COMPLETE MACHINING OF YOUR TURNED PARTS:

VERTICAL INTEGRATION AND VARIETY

In addition to CNC turning technology and multi-spindle technology, Schuler also employees a wide variety of CNC machining centres as well as special machines.

This tremendous vertical integration makes us your universal system partner for ready-to-assemble workpieces and assemblies.